Fuel level sensors are indispensable devices that have revolutionized the way we monitor and manage fuel in various applications, from vehicles and industrial machinery to storage tanks. These sensors offer precise measurements of fuel levels, ensuring efficient fuel management. Let’s take a closer look at the significance of fuel level sensors.

**How Fuel Level Sensors Work:**

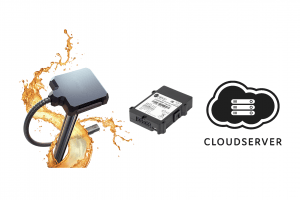

Fuel level sensors utilize various technologies, including ultrasonic, capacitive, or resistive methods, to accurately measure the level of fuel in a tank or reservoir. These sensors are typically installed inside the fuel tank, and they generate data based on the fuel’s height or volume. The collected data is then transmitted to a central monitoring system or dashboard for analysis.

**Benefits of Fuel Level Sensors:**

1. **Accurate Fuel Monitoring:**

Fuel level sensors provide real-time and highly accurate data on fuel levels, ensuring that you have a precise understanding of how much fuel is available at any given time.

2. **Efficient Fuel Management:**

With accurate data at your fingertips, you can make informed decisions about fuel replenishment, route planning, and equipment operation, ultimately reducing fuel wastage and optimizing efficiency.

3. **Cost Savings:**

By minimizing fuel consumption and avoiding run-out situations, fuel level sensors can lead to substantial cost savings for both individuals and businesses.

4. **Prevention of Fuel Theft:**

Fuel level sensors can also be used to deter and detect fuel theft or unauthorized use of fuel, which is a common concern in certain industries.

5. **Environmental Responsibility:**

With precise fuel monitoring, you can better manage your environmental footprint by reducing unnecessary fuel consumption and emissions.

**Applications of Fuel Level Sensors:**

1. **Automotive Industry:**

In vehicles, fuel level sensors provide accurate fuel gauge readings, allowing drivers to monitor their fuel levels and avoid running out of gas.

2. **Fleet Management:**

For businesses with vehicle fleets, fuel level sensors are invaluable in optimizing routes and fuel usage, leading to cost savings and improved efficiency. Check out our fleet management solutions here.

3. **Aviation:**

Fuel level sensors play a crucial role in aircraft, ensuring that there is sufficient fuel for the entire journey and contributing to the safety of flights.

4. **Industrial Machinery:**

Fuel level sensors are used in various industrial applications, including heavy machinery and generators, to ensure that equipment operates smoothly and without interruptions.

In conclusion, fuel level sensors have become essential tools in a wide range of industries, offering precise monitoring and efficient fuel management. Whether you’re an individual looking to keep an eye on your vehicle’s fuel level or a business aiming to optimize your fleet’s efficiency, these sensors play a vital role in cost savings and responsible resource management. Their accuracy and reliability make them a valuable asset in today’s world of fuel-dependent operations.

WRITTEN BY : WJ VEITCH